Bayaya’s automated production facilities enables us to produce 20,000 pcs of game cards per day, ensuring your order of high-grade board and card games is completed on time.

Our automated shop shortens production cycles and contributes to efficiency and quality rates in quality inspection as our cards are produced according to standard process.

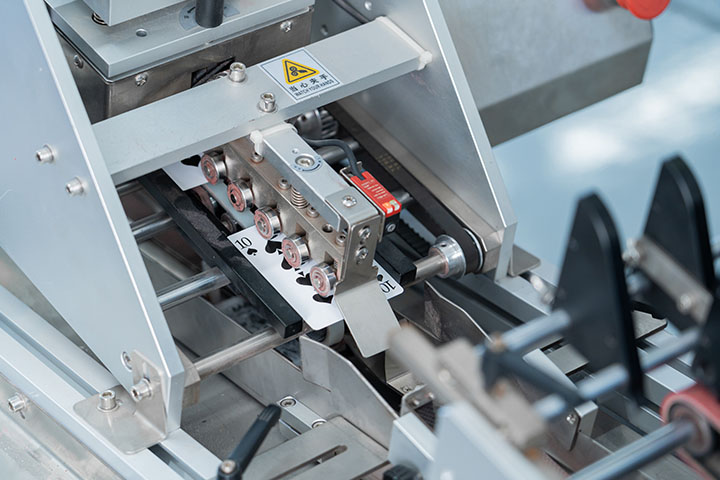

The automatic trimming machine helps to cut the corners and edges of the cards with better precision. The ±0.01mm deviation makes our cards stand out in the market with undeniable cutting accuracy.

The card stiffness is improved thanks to our automatic oiling and drying machine that offer twice treatment on the cards.

An accurate trimming machine automatically cuts the cards into the specified dimensions without any burrs or defects.

We protect your IP right when manufacturing your cards through our automated facilities using the advanced anti-counterfeit papers.

You can stay ahead in the gaming market when working with Bayaya due to the following advantages.

Our automated production line utilizes the latest Industry 4.0 technology for superior efficiency and flexibility in manufacturing your cards.

We offer competitive prices when producing your cards and games by automating most of our factory and decreasing manual labor.

All board game pieces have a consistent quality and appearance thanks to the accuracy and efficiency of our automation solutions.

The speed and precision of our automated machines can complete bulk orders within the expected delivery date without sacrificing quality.

Bayaya can minimize raw material waste and power consumption due to our Industry 4.0 technology-powered automation capabilities.

*We respect your confidentiality and all information are protected.

*Please upload only jpg, png, pdf, dxf, dwg files. *Size limit is 10MB.

Copyright © 2023, Bayaya. All rights reserved. Powered by MML.